The continual improvement process, also known as Kaizen, describes the steps a company takes to identify and eliminate waste, inefficiencies, and weaknesses across its products, services, and business processes. This drives better, cheaper, and faster outcomes.

For example, a trucking company cutting fuel costs with route optimization software, or a clinic cutting patient wait times through a new scheduling system, are both examples of continual improvements.

That said, innovation managers often face resistance and silos in large organizations when implementing continual improvement processes, preventing them from turning ideas into actual improvements.

In this article, we share the exact steps we’ve used over 15+ years as innovation consultants to implement continual improvement processes at major companies like DHL, Visa, Novo Nordisk, and ING. This process is inspired by the Plan-Do-Check-Act (PDCA) continuous improvement framework.

We’ll also review how our innovation software, InnovationCast, supports companies in building a more productive continual improvement model.

1. Collect Ideas on How to Improve Products, Services & Processes

The first step in the continual improvement process is to generate ideas that highlight improvement areas and potential solutions.

From our experience, the best way to do this is by creating an outlet where employees can freely share incremental changes they want to see. This taps into the daily insights of front-line workers:

Where do they see the company wasting money? What are customers frequently complaining about? How can we streamline processes?

Although there are significant benefits to involving the entire workforce, the way you solicit ideas significantly influences how engaged and willing employees are to contribute.

Most companies take a passive approach to gathering ideas. They set up an email inbox or a Microsoft Teams channel for employees to send suggestions. But this “idea box” approach has three major flaws:

No transparency: Once employees submit ideas, they can’t track if teams are reviewing, testing, or even considering them. They often assume their idea has been rejected or forgotten — so they stop participating.

Lack of education on continuous improvement: Many employees don’t see value in incremental improvement, assuming companies only want disruptive ideas from scientists and engineers. The idea box doesn’t encourage an improvement mindset, so employees hold back.

No urgency to contribute: An always-open email or Slack channel creates no sense of urgency for sharing ideas, making it difficult for companies to quickly collect ideas.

How InnovationCast Helps Companies Surface Improvement Opportunities

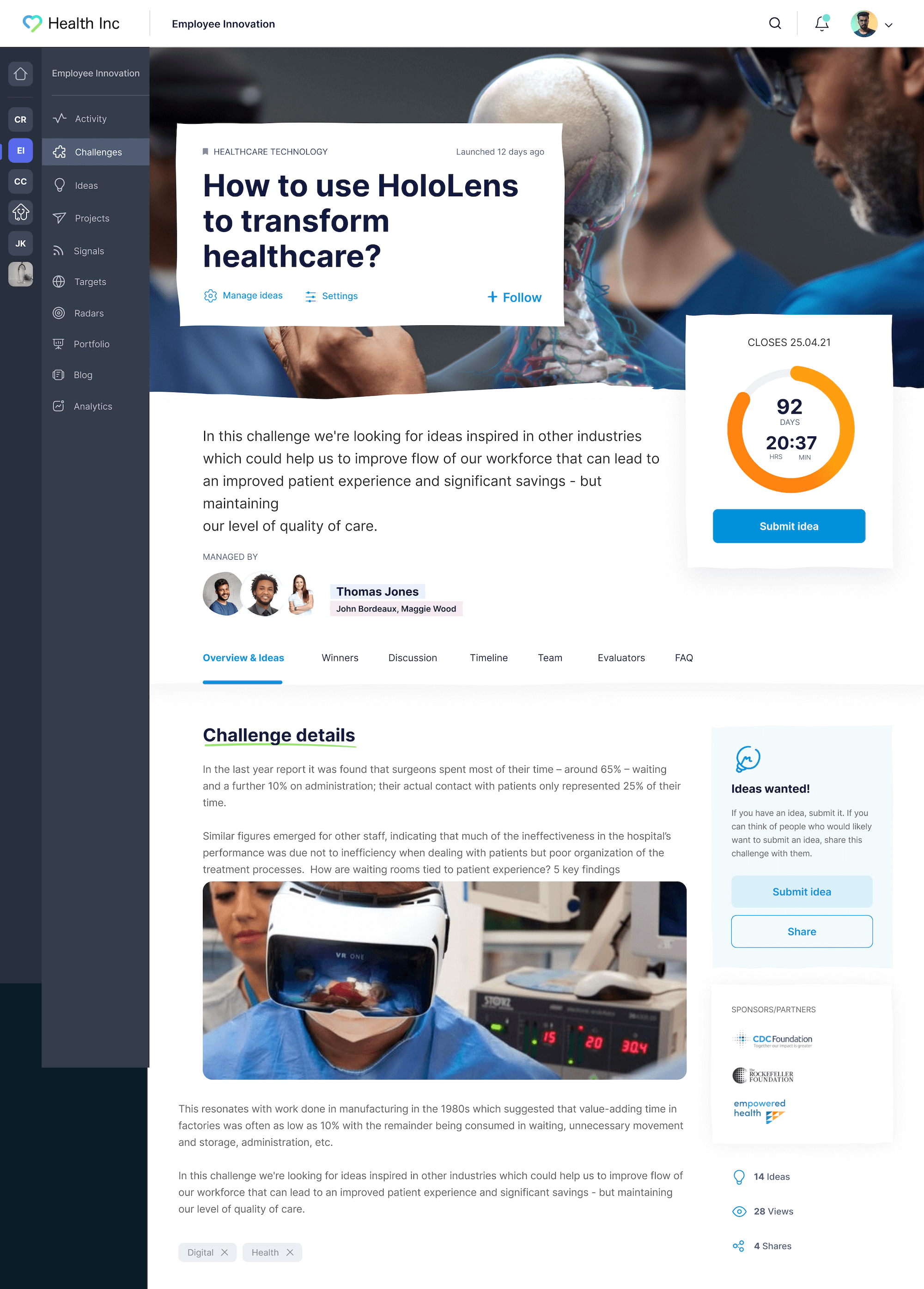

We built InnovationCast with a feature called Innovation Challenges to overcome the limitations of the traditional idea box and spark high-quality contributions from employees.

Innovation Challenges invite employees to share ideas on specific topics — like areas for improvement — by a set deadline. Each challenge includes detailed background to ensure employees understand the context before responding.

Any stakeholder can create a challenge outlining which area of business they’d like to improve (e.g., existing processes, wasted capital, bottlenecks, product weaknesses), and InnovationCast sends each employee an email prompting them to get involved.

Once employees submit their ideas, they can track them from conception to implementation and get notified if further input is needed. This transparency shows their time and effort are valued, improving long-term employee engagement.

In addition, when employees are invited to join InnovationCast, we send short, periodic emails showing how their insights create real value for the company. This helped us achieve 80%+ participation rates with companies like DHL and Visa.

Read more: How to Encourage Innovation in the Workplace

2. Allow Employees to View Their Colleagues’ Ideas & Encourage Collaboration

It’s fine to send incremental improvement ideas to an evaluator who decides whether or not to implement them. But organizations that truly foster a culture of innovation send ideas to refinement first.

During refinement, employees with diverse skills from various departments can view colleagues' improvement ideas and share their thoughts, questions, and suggestions — collaborating to refine them. As a result, companies collect more complete, higher-quality ideas.

Yet most companies’ continual improvement processes leave little room for refinement. Ideas pile up in email inboxes or Slack channels with no dedicated workspace for employees to view and improve submissions across the organization.

Even when companies try informal improvement initiatives by displaying ideas in Slack or Google Docs, they lack key community features (e.g., voting, public recognition, comment threads, automated email prompts) that engage employees in developing those ideas further.

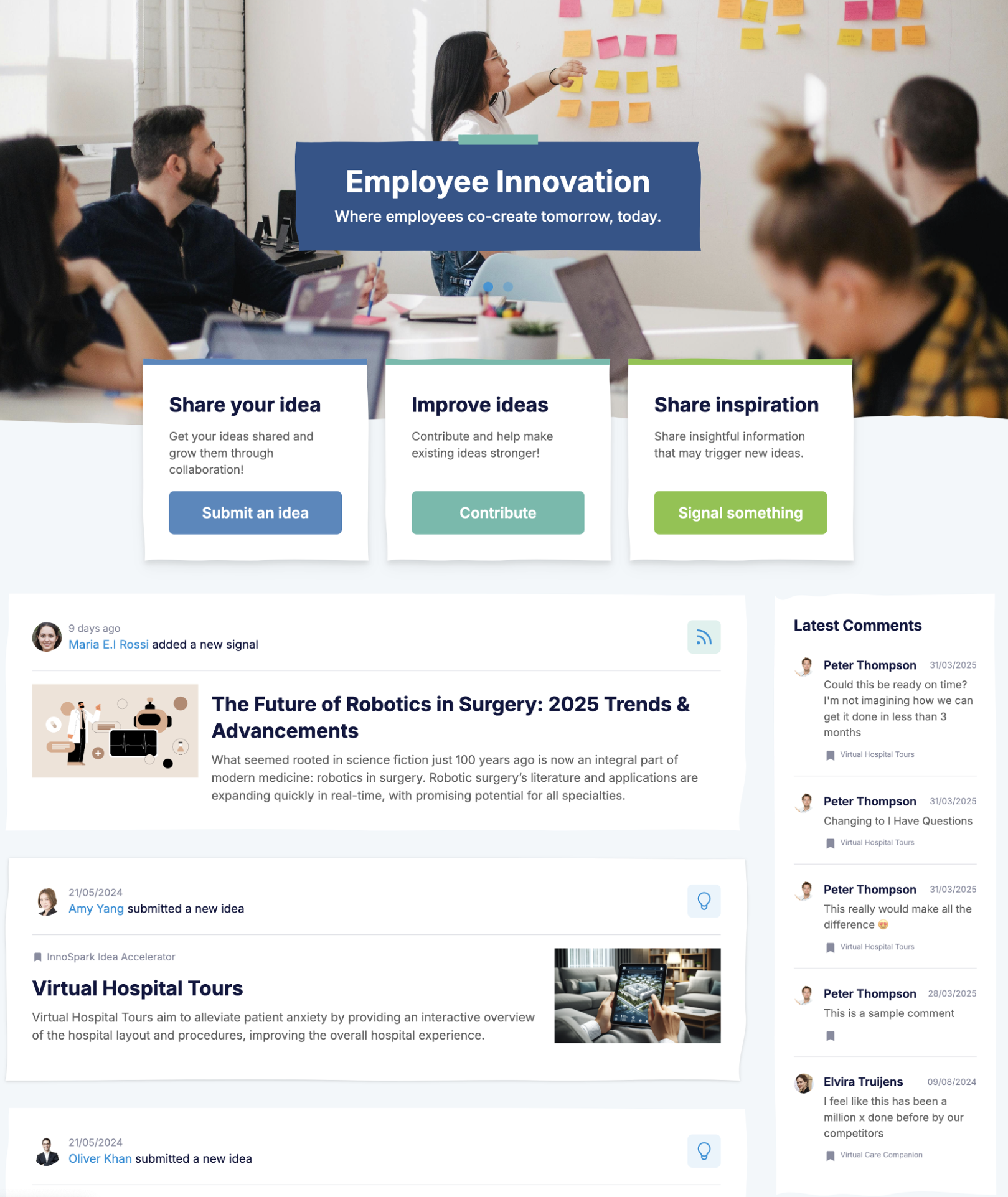

InnovationCast was designed to solve this by tapping into the expertise of the entire workforce.

How InnovationCast Enables Companies to Refine Ideas

Once an improvement idea is submitted, it’s automatically posted to the InnovationCast newsfeed, where other employees can view it as soon as they sign in.

As users scroll through their newsfeed, they can see the most recent ideas along with any additional information that the author has added — such as the reasoning behind the change, evidence supporting their idea, expected impact, and potential risks or trade-offs.

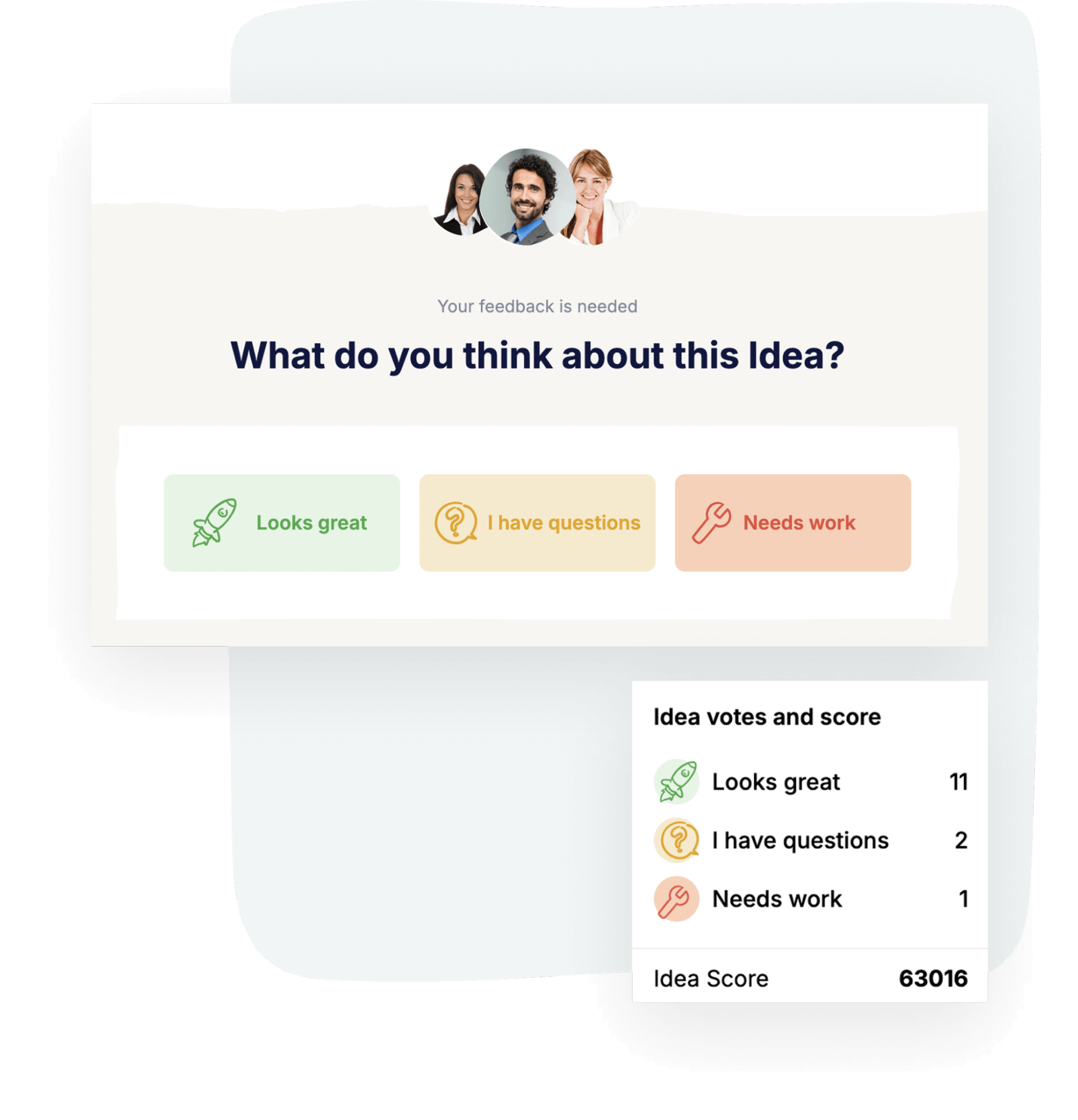

InnovationCast prompts users to review these ideas and suggest improvements. The voting feature lets them indicate whether an idea “Looks great,” “I have questions,” or “Needs work.”

Most importantly, InnovationCast prompts users to explain the reasoning behind their vote. Why do they believe the improvement will work? What makes them doubt its success? The author is notified whenever someone votes and leaves feedback.

As idea authors and colleagues co-develop and iterate on the idea, InnovationCast saves each iteration, making it easy for stakeholders to track the idea’s evolution since conception.

Read more: 6 Steps to Creating a Culture of Continuous Improvement Within an Organization

3. Evaluate the Potential Impact, Risk & Cost of the Change, Among Other Considerations

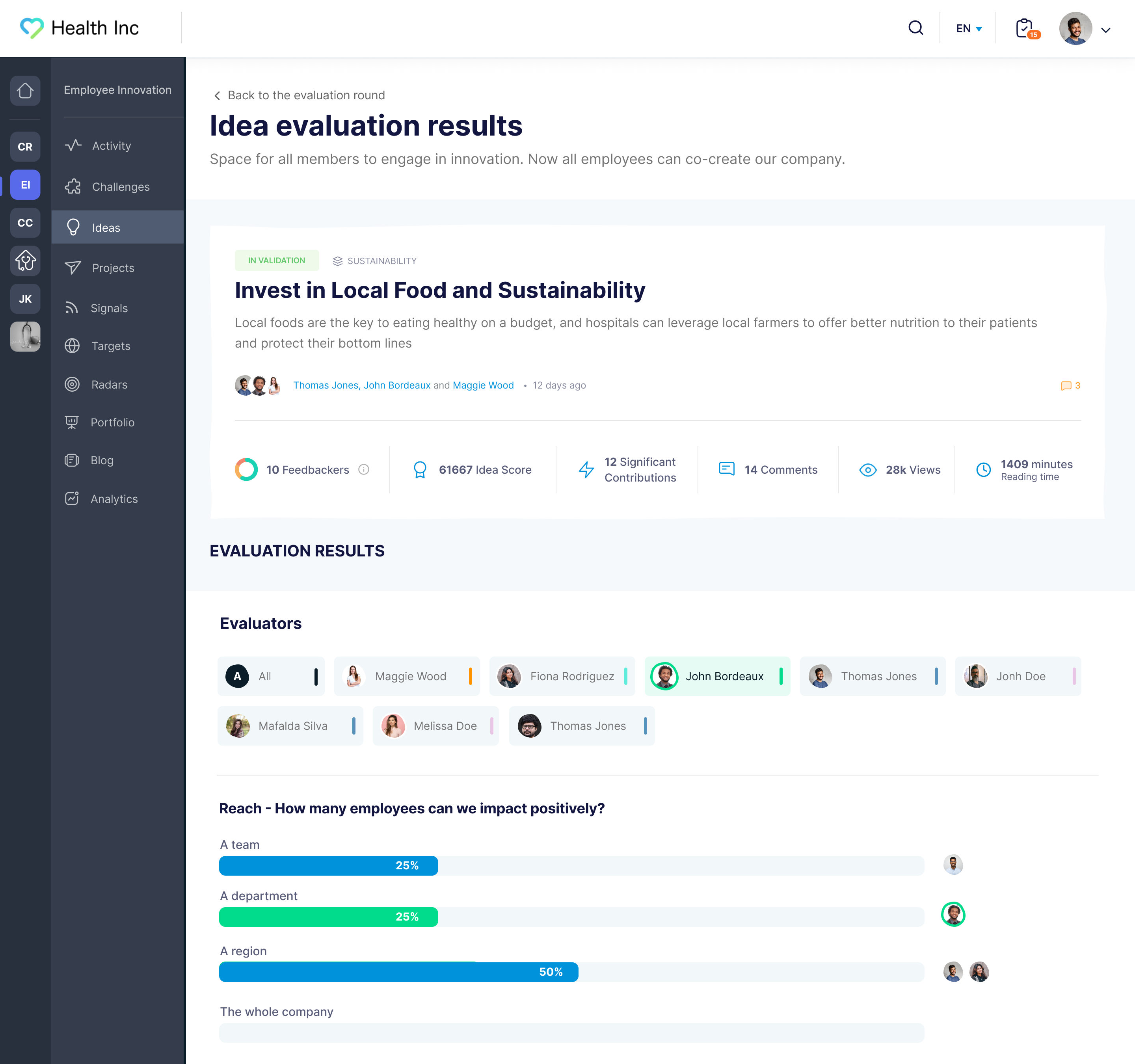

Once employees have submitted and refined their ideas, they’re handed off to a domain expert with relevant expertise. The expert evaluates the idea and decides whether to greenlight it.

To guide this decision, the evaluator uses an evaluation model — a set of questions covering the idea's evidence, impact, cost, and other factors. For each question, the evaluator gives a score. If the idea meets the minimum score threshold, it’s approved.

In addition, the company can't implement every change at once without disrupting day-to-day operations. So, they test one idea at a time, starting with those that show the most potential and carry the least uncertainty.

The issue with how most companies evaluate and prioritize ideas is that the process is entirely ad hoc, typically handled through a few evaluators’ email inboxes. This makes evaluation time-consuming and disorganized.

Each time an idea is approved, declined, or requires small changes, evaluators must manually contact the author. If evaluators want to review the previous version of the idea, they need to dig through numerous emails. Improvement efforts and conversations get lost, and evaluators spend more time on administrative tasks and communication than actually evaluating the ideas themselves.

We created InnovationCast with initiative dashboards and automation features, enabling evaluators to manage hundreds of ideas with minimal effort.

How InnovationCast Automates the Evaluation Process

Rather than sifting through email inboxes and individually messaging each idea author, evaluators can log in to InnovationCast and view all the ideas that still need evaluation alongside those that have already been approved or rejected.

Then, evaluators can click into an idea, view all the evidence the idea author has added, and use our evaluation models to help them score the idea. InnovationCast comes with several evaluation models, including RICE, ICE, and Value vs. Effort, among others.

Evaluators can assign a score to each question in the model, and once an idea reaches the minimum score, InnovationCast automatically sends the author an email notification. We also notify relevant teams that they need to test the effectiveness of the idea before implementation (more about that below).

4. Test the Improvement on a Small Scale and Compare Results to the Current Process

Before the company launches the full-scale change, it first needs to know whether it performs better than what is currently being done. So, they launch the change on a small scale.

For example, if the ongoing improvement involves a new internal communication platform, the company might pilot it within the sales department to observe its impact on collaboration and response times.

Or, if the improvement focuses on using a new, stronger material in the manufacturing process, the company might first test it on a single product line or within a limited production run to evaluate factors such as durability, cost efficiency, and compatibility.

To test ideas, companies typically assemble a validation team, which consists of three employees: an engineer, a marketer, and a designer. This team is responsible for identifying key risk factors that might cause the change to fail and running experiments to test them.

For example, if an employee proposes using an experimental, potentially stronger material for their product, they might identify these risk factors:

Risk factor: The new material may not be stronger than the current one.

Experiment: Run side-by-side lab strength tests.

Risk factor: Production costs could exceed acceptable margins.

Experiment: Perform a cost analysis comparing current vs. new material across production volumes.

Risk factor: The new material might not meet safety standards.

Experiment: Conduct lab certification tests and third-party compliance evaluations.

The validation team and top management review each experiment’s results, comparing them to current metrics to decide whether to implement or discard the idea.

A common mistake companies make is skipping proper testing setup. Without clear structures, ideas remain dormant, no one knows their role, and there's no central place to measure progress.

How InnovationCast Helps Teams Test Small Improvement Ideas

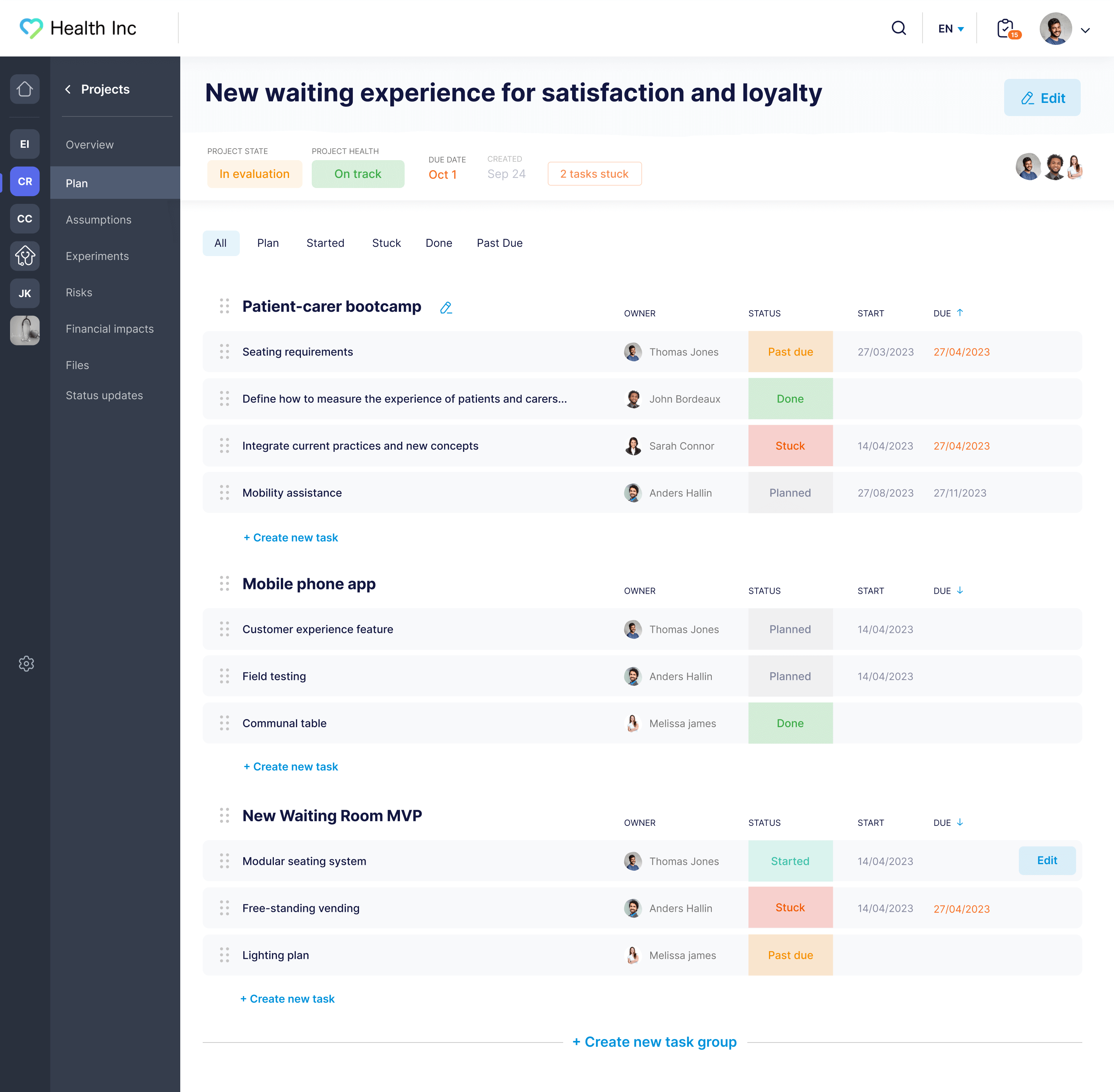

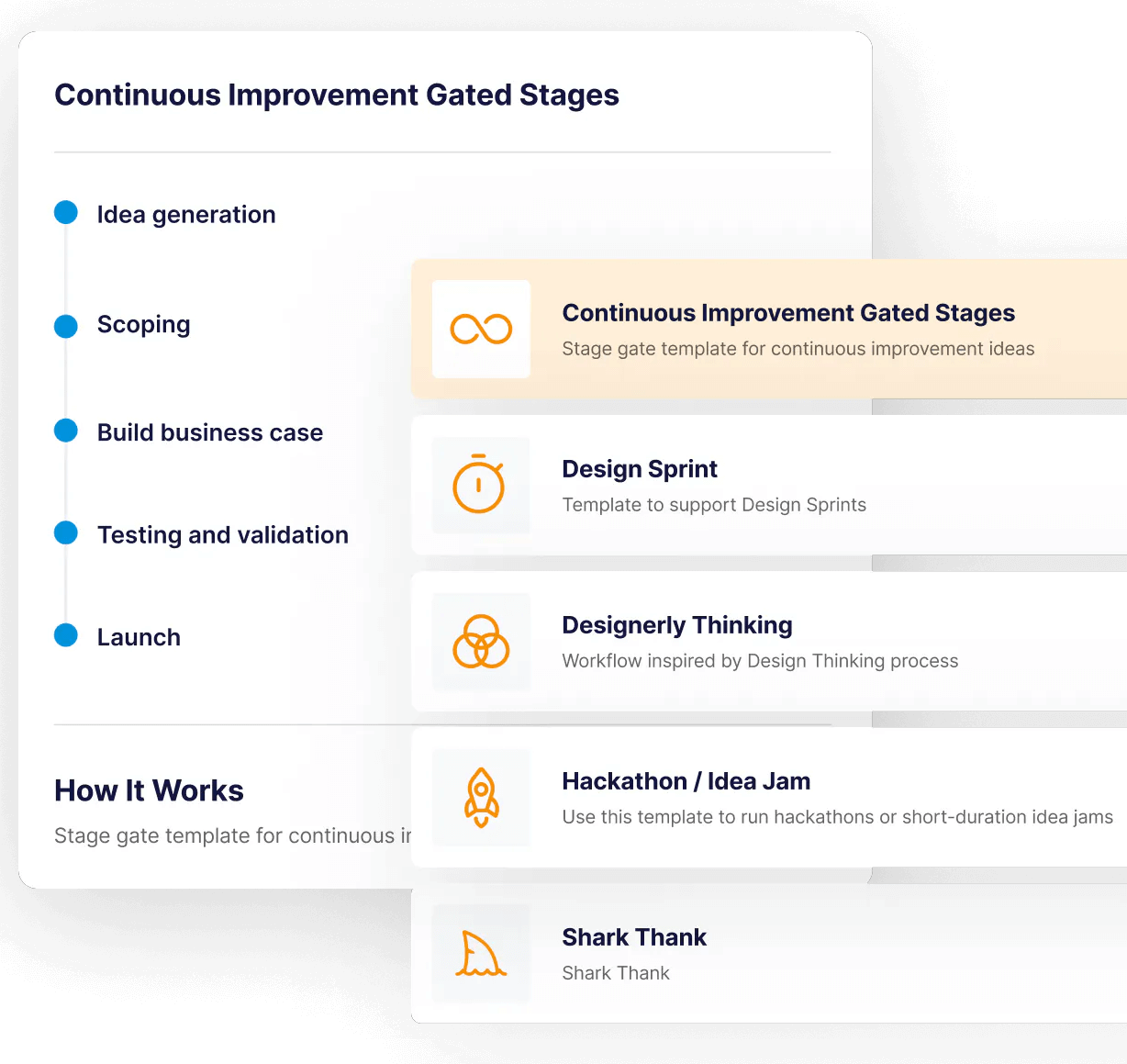

InnovationCast includes detailed idea evaluation and validation workflows that guide teams through each step after an idea is collected.

This typically involves identifying key risks, designing effective experiments, performing process mapping, conducting root cause analysis, and knowing when and how to pivot.

Stakeholders can assign each task in the workflow to a specific employee or team, and InnovationCast notifies them when they need to step in, ensuring everyone knows what’s required. When they are finished, the person owning the next task in the workflow is notified. This keeps ideas moving forward.

Workflows are easy to customize with drag-and-drop design blocks — no coding required.

Based on our experience as innovation consultants, these workflows draw inspiration from Six Sigma, Agile, Lean Methodology, Total Quality Management, Lean Manufacturing, and other improvement methodologies.

Stakeholders can also use the InnovationCast reporting dashboard to track ideas in progress, budget allocation, test outcomes, and decide which improvements to implement.

Read more: 5 Steps to Establish an Effective Corporate Innovation Program

5. Implement Changes at Scale

If teams see the change meet or exceed expectations and outperform the current iteration, they give the project management team the greenlight to implement it across the organization.

Continuing with the product example above, if the limited production run using the new material proves more durable, top management will authorize its use across the production line.

After implementation, relevant teams continue monitoring real-time performance (like customer satisfaction, employee involvement, and operational excellence) to identify any adjustments needed to sustain or improve its impact.

The continual improvement process is an ongoing effort, meaning once improvements are implemented, the PDCA cycle starts again from the beginning.

Implement a Productive Continual Improvement Program Within Your Organization Using InnovationCast

Schedule a free demo with our team to see how InnovationCast can help you achieve your continual improvement goals.